まだ見ぬ

“創造”を求めて

Welcome to Showa, where we fearlessly face the challenges, embrace innovation, and forge ahead to create a better future.We believe in breaking the mold and redefining industry standards.Join us as we open new horizons and shape a brighter tomorrow.

NEWS

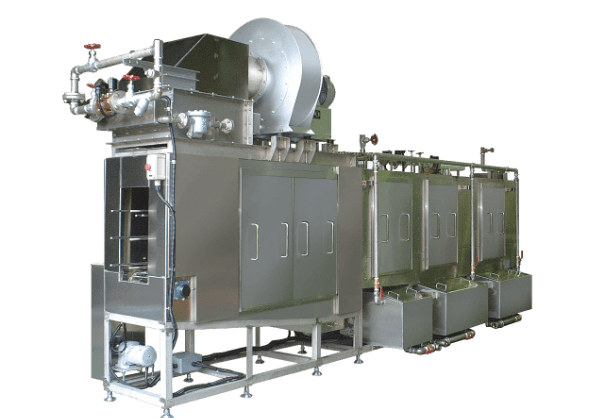

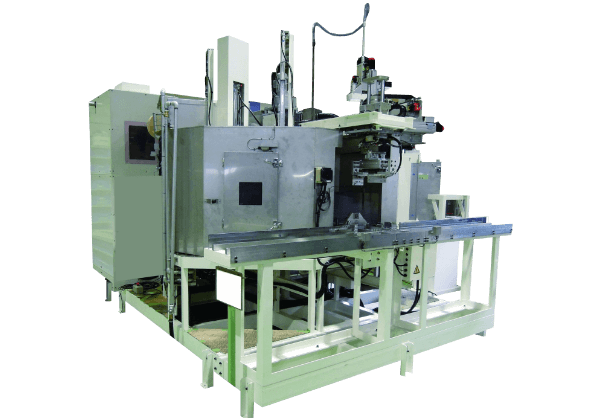

BUSINESS